Problems with Aluminum Wiring

The leading cause of electrical fires in Canada is faulty wiring. Homes with aluminum wiring are at much higher risk than others with copper. The association of certified home inspectors states problems with aluminum wiring as a possibe dangerous electrical conductor. Canadian based, Square One Insurance Services asserts that where copper and aluminum wiring have been mixed in homes, it presents a risk in the lack of correct connectors.

The Electrical Safety Authority published in June 2019 that attention regarding the protection of aluminum wiring was growing. Because of the possible fire hazard, you may see difficulties insuring your home if it has aluminum wiring. Soon after aluminum wiring became widespread, some dilemmas started to emerge. These included, warm cover plates on switches and receptacles, burned insulation on wiring, and flickering lights. There was an overheating concern, and overheating can suggest fires.

Authorities looked into it and discovered there were three additional differences between aluminum and copper.

1) Rusting: When metal rusts, it oxidizes. Oxidized copper is still conductive, where aluminum is not so much. Thus interfering with the flow of electricity.

2) Softness: Aluminum is a lot softer than copper. It is much easier to nick or break.

3) Cold Creep: Wire heats up when electrons flow through it. Aluminum expands when heated. Continous expansion and contraction cause connections to loosen.

Since 2003, the Electrical Safety Authority has received a growing number of inquiries about the usability of aluminum wiring. Especially from purchasers or owners of homes built from the mid-1960s until the late 1970s with aluminum wiring. Many insurers will not produce or renew insurance coverage on properties without the wiring getting inspected.

An electrician can determine if repair or replacement is necessary for the certificate of inspection. The contractor should do an assessment and make the required repairs. ESA would then provide a certificate to pass along to the insurer. Homeowners should also obtain a copy of the Certificate of Inspection for their records. In some instances, the insurer may want replacement of the aluminum wiring with copper wiring. Verify with your insurance firm for their requirements.

Houses are all different and must get evaluated on their own. It is highly advised the homeowner choose a licensed electrical contractor that is knowledgeable in the particular techniques required for working with and repairing aluminum wiring.

How to Determine Problems with Aluminum Wiring

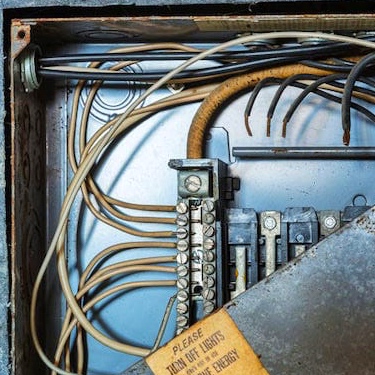

As mentioned above, Problems for aluminum wiring usually exist at termination points. It requires the uncovering of all outlets, switches, fixtures, receptacles, appliance connections, and in the panel. Visually examine terminations for indications of failure and overheating without shifting or disrupting the devices or wiring. No signs of overheating, such as discolored or darkened connections, melted insulation, should get found.

If you can see the wire insulation, it will be marked every 12 inches with AL, Aluminum, or ALUM. Where problems get noticed, the damaged aluminum conductors should get cut back to remove the damaged portion and then make the required repairs. It is also encouraged to inspect aluminum wiring systems every 4-5 years or so.

Always seek help from a professional electrician before attempting any work yourself. Contact Mike Fuller Electric today for your aluminum wire inquires.

Tel: (613) 225-3249

Email: [email protected]

Get a Free Quote

Location

Mike Fuller Electric Ltd.

1692 Ortona Avenue

Ottawa ON

K2C1W7

Working hours

Monday-Friday: 7AM-4PM

By appointment on Saturday and Sundays

© 2018 Mike Fuller Electric Inc. All rights reserved | Privacy policy | Terms of service